TECHNOLOGY

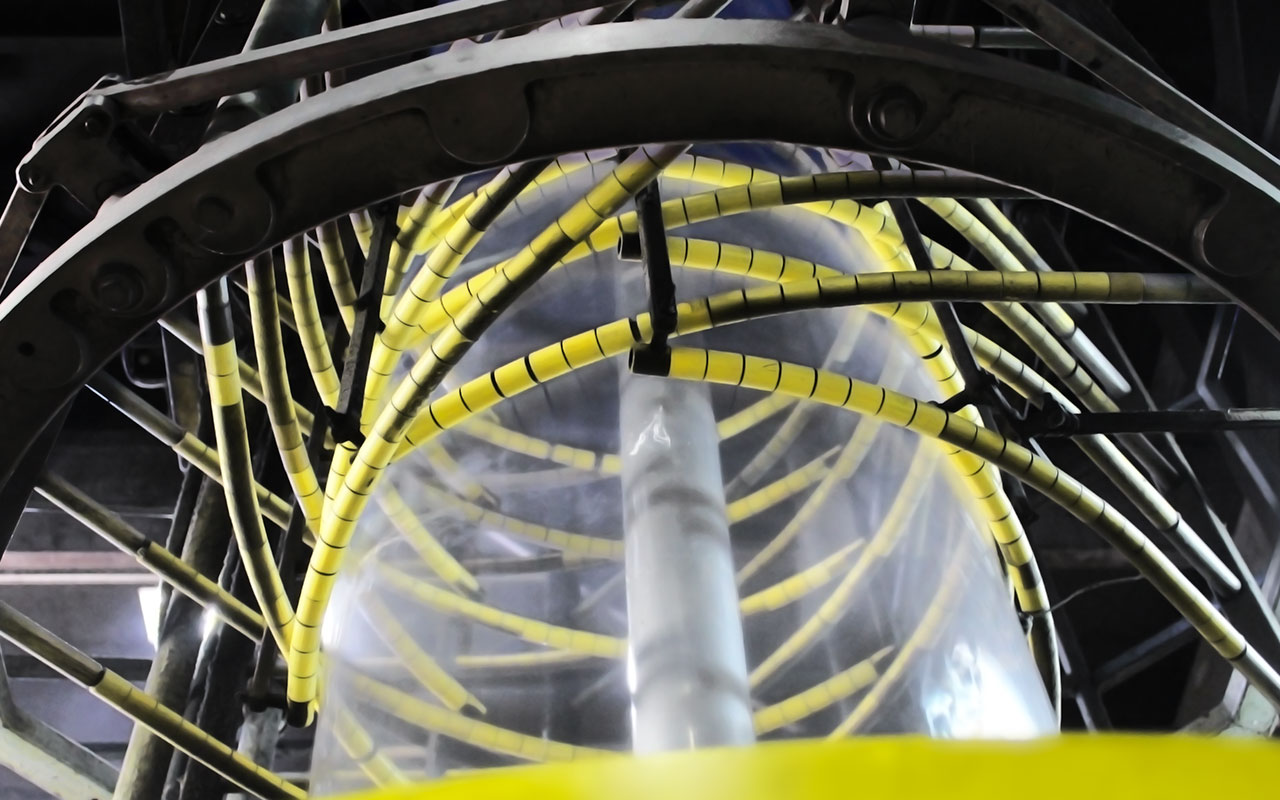

FILM EXTRUSION

Our internal extrusion department guarantees maximum flexibility in production, both in blow film and cast film; we constantly assure our customers fast and impeccable delivery times. We stand out for the high quality of our raw materials and for the research we do every day, trying to solve the many problems related to extrusion processes to the best of our ability.

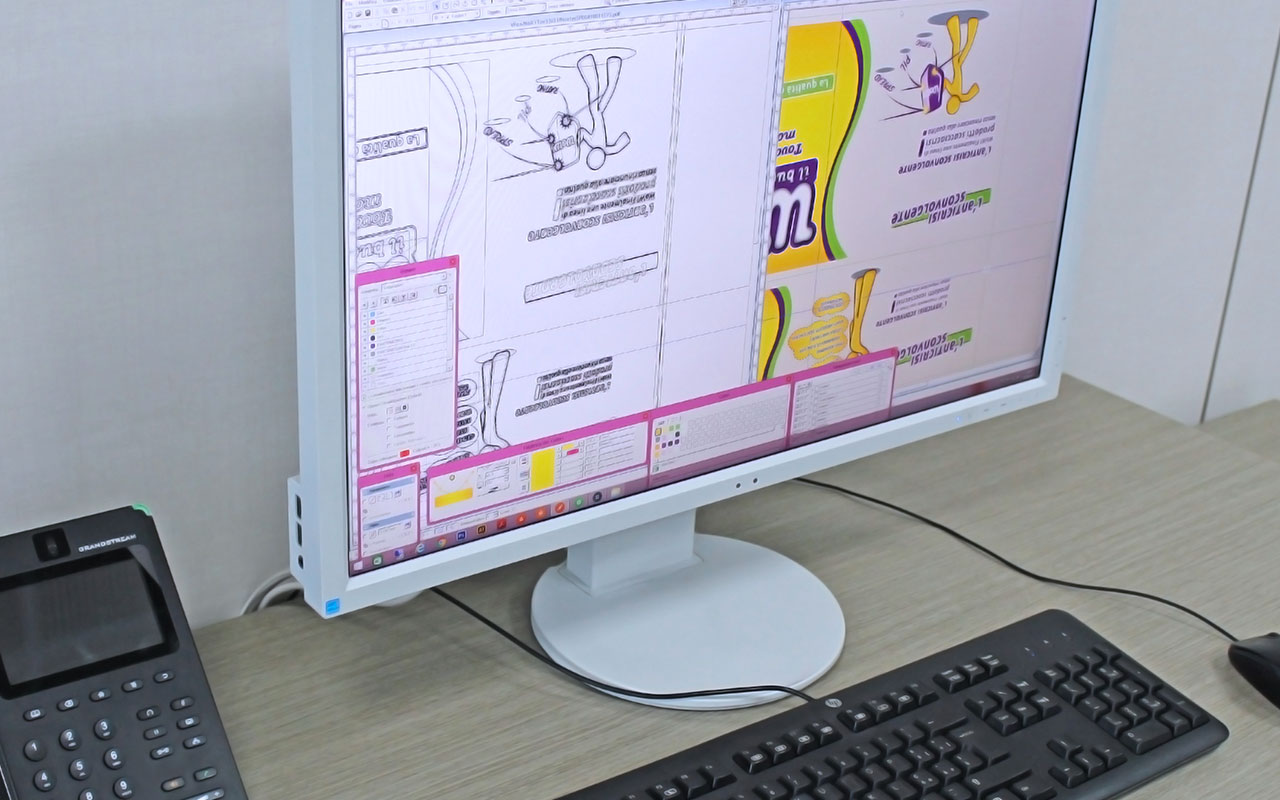

PRE-PRESS

Good pre-press work is a fundamental step for the realization of a quality packaging. The experience of our technicians, and the investments to keep pace with the continuous evolution of the information technology sector, have allowed us to optimize our workflow, starting from the processing of graphic files to colour proofs, the engraving of the plates with Full HD system.

FLEXO PRINT

The sophisticated technology of our systems and the professionalism of the operators are our strong point. The accurate checks that are carried out throughout the production process guarantee a remarkable print quality.

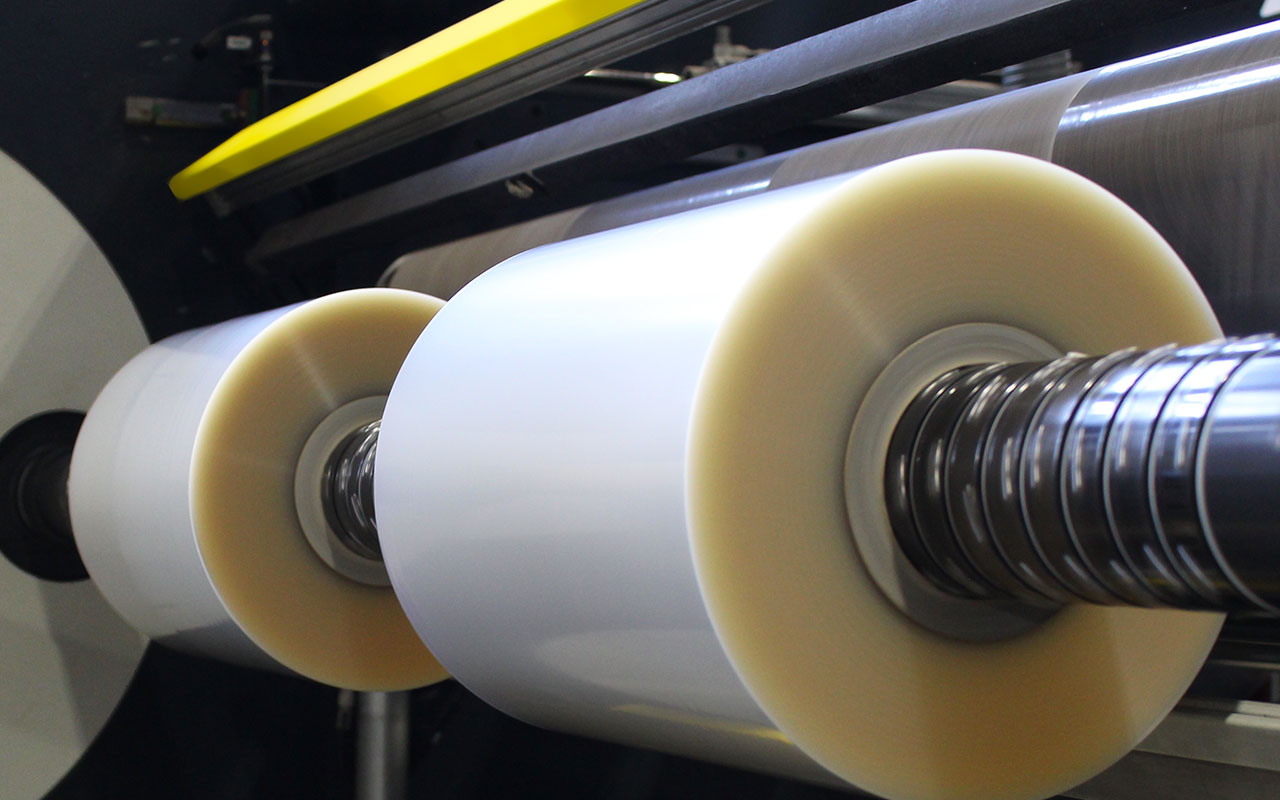

ROLLS LAMINATION

Our many years of experience, combined with cutting-edge technology, allow us to produce high-performance laminates. These can be made either with barrier layer or without. The presence of a barrier layer allows a better and long shelf life of your products over time. The use of the solvent-free system with latest generation adhesives, is able to guarantee the absence of aromatic amines and substances that could contaminate the product for which the films are intended.

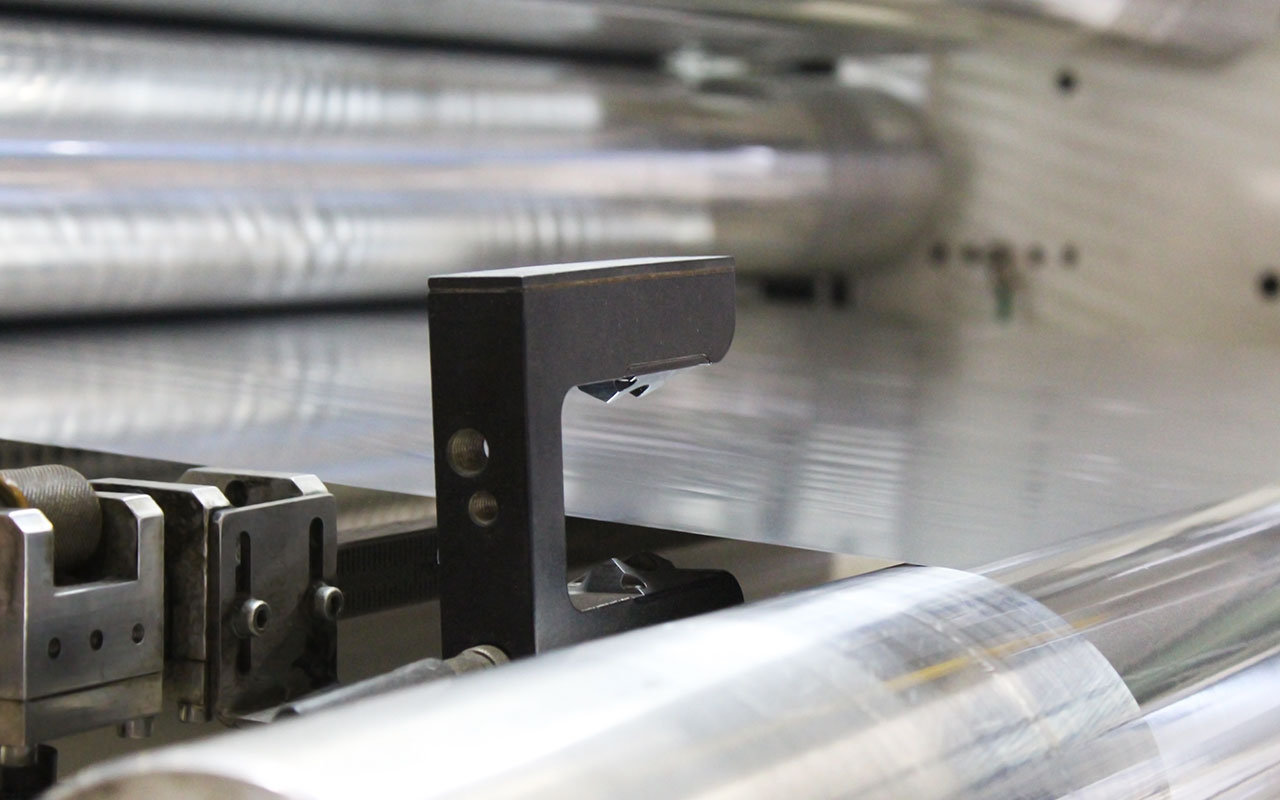

SLITTER REWINDER

Film in rolls are trimmed thanks to the help of laser positioners, which direct the circular knives to obtain a perfect cut and constant dimensions. Modern transducers regulate the tension, ensuring a uniform unwinding from the beginning to the end of the roll.

BAGS PRODUCTION

We are always attentive to Customer needs, so we offer a wide range of bags to meet the demands of a constantly evolving market. Thanks to the modularity of our pouch machines we are able to offer customized solutions, ranging from traditional bags, to those with riveted corners, from flat bottom bag at the new patented cross-stitch pattern, to embossed and micro-perforated bags, wicket bags, bags for shipments, and to those with anti-tampering security tape.

LABORATORY

In our structure, an internal laboratory is present through which we carry out meticulous tests, constantly monitoring the production process. We collaborate with Certified Laboratories and Research Institutes for the development of quality and innovative projects.

ENVIRONMENT

We are always sensitive to issues related to the environment, we adopt a standard in accordance to ISO 14000 regulation. Atmospheric emissions are constantly monitored. We rely on certified external companies for waste disposal.